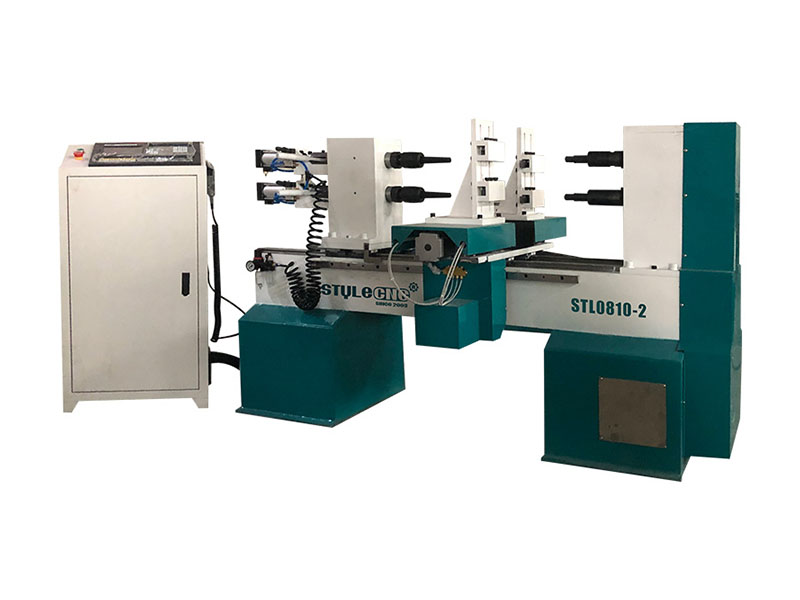

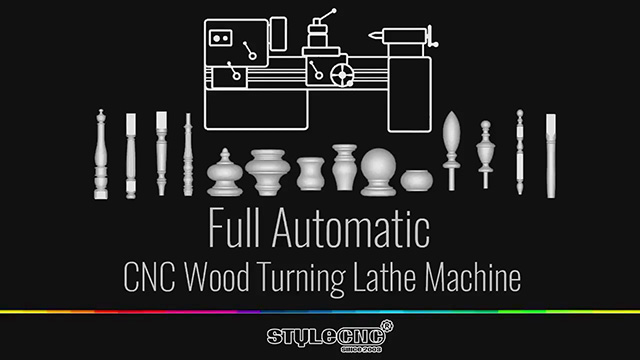

No. 1 Hobby Wood Lathe Machine for Sale

Hobby wood lathe machine is applied in small business, small shop, home business, home shop for barrel, Bead, buddha heads, hoist pieces, gourd pendant, wood cup, whip, bowl, cigarette holder, eggs, scroll painting head, pens, ashtray and wine stoppers, etc.

Technical Parameters

| Brand | STYLECNC |

| Model | STL1040 |

| Turning Length | 5mm - 400mm |

| Turning Diameter | 5mm - 100mm |

| Axis | Single Axis |

| Applications | Wood Turning |

| Ratings | 4.9/5 based on 55 votes |

Pirce Range

$2000.00 - $3000.00